Products We Provide

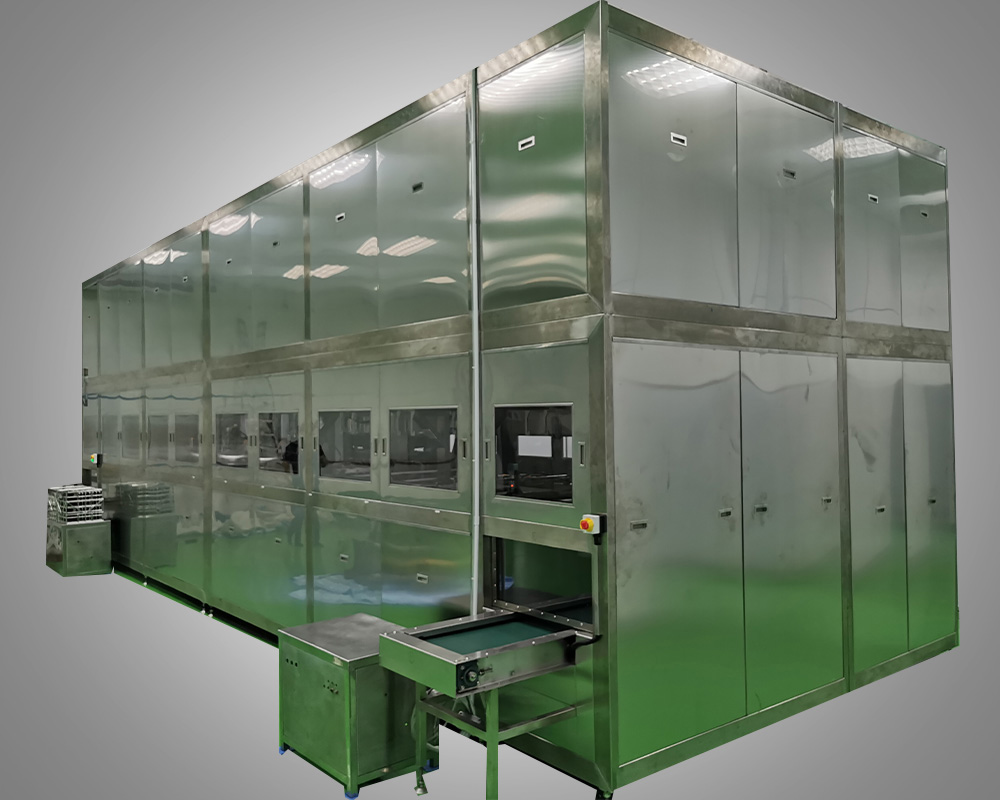

Chemical Cleaning System

We are working closely with our chemical supplier, Kyzen to offer the best solution in term of quality, efficiency and our beloved nature.

KYZEN offers safe and effective metal finishing products which address a wide range of manufacturing requirements, for cleaning and protecting metal parts.

2. Main cleaning

3. Rinsing

4. Rinsing with deionised water

5. Rinsing with corrosion protection

6. Drying

Application

Aerospace

Electronics

Optics

Automative

Medical

Power Generation

Defense

Oil & Gas

Semiconductors

Surface Plating System

Surface plating system is commonly used to protected the mother material with a thin film of metal on a conductive surface. Plating is versatile function namely for decorative objects, for corrosion inhibition, to improve solderability, to harden, to improve wearability, to reduce friction, to improve paint adhesion, to alter conductivity, to improve IR reflectivity, for radiation shielding, and for other purposes.

The major components used in our system are reliable, serviceable and has been proven in the industries. Therefore, the downtime for our system relatively minimum as compared to conventional design. For example, we are using motors with braking system to ensure smooth running. The reliable brakes coupled with fully automated PLC control. The system is operated with option of human interphase of touch screen or computer SCADA system. The user-friendly HMI is easily managed by operator either during normal operation or troubleshooting.

Application

Aerospace

Electronics

Optics

Automative

Medical

Power Generation

Defense

Oil & Gas

Semiconductors

Tooling Hardening System

Diamond like coating can be amorphous, more or less flexible, hard, strong, and slick according to the composition and processing method. Benefits include wear and abrasion resistance, low Friction, high hardness, antireflective properties, corrosion resistance, gas barrier effect. Some commercial and industrial applications of diamond like coating protective coatings concern sectors as diversified as aerospace, automotive, cosmetics, bearings, electronics, industrial wear parts, textiles…

- Optical products to create a hard, low-friction, scratch-resistant surface (glass, plastics, mirrors)

- Medical products including implantable joints, catheters, surgical implements, medical instrumentation and packaging

- Thermal applications including thermal print heads and passivation of electronic circuitry

- Barrier applications including pharmaceutical packaging and medical productstorage

- Wear applications including plastic molds, gear pumps, extrusion dies,stamping devices, process equipment, magnetic tape heads and computerhard disks

Ultrasonic Cleaning System

Application

Disk Drive Components

Sporting

Automotive

Engineering & Weapons Industries

Printing

Electroplating

Medical & pharmaceutical

Marine

Vacuum Pressure Impregnation System

Application

Aerospace

Electronics

Automative

Defense

Industrial Oven

Ovens are widely used in many different applications, including chemical processing, food production and electronics industry.

Application

Disk Drive Components

Sporting

Automotive

Engineering & Weapons Industries

Printing

Medical & pharmaceutical

Marine

Offline Cleaning System

1. Small production unit if the parts demand is low and essential.

2. Pilot production system before scales up.

3. Testing with varies chemical and process parameter before mass production.

4. Optional installation of heater, cooling system, ultrasonic, mechanical and air agitation.

The system is mobile, small in size and simple in operation. Suitable use in laboratory, control room or placed side by side with existing production lines.

Application

Disk Drive Components

Electroplating

Automotive

Engineering & Weapons Industries

Laboratory

Défense & Military

Medical & pharmaceutical

Marine

Customized Jig

Discussed with our experienced team to customize jigs and fixture in order to increase productivity, at the same time increase in product quality!

Customized PP Barrel

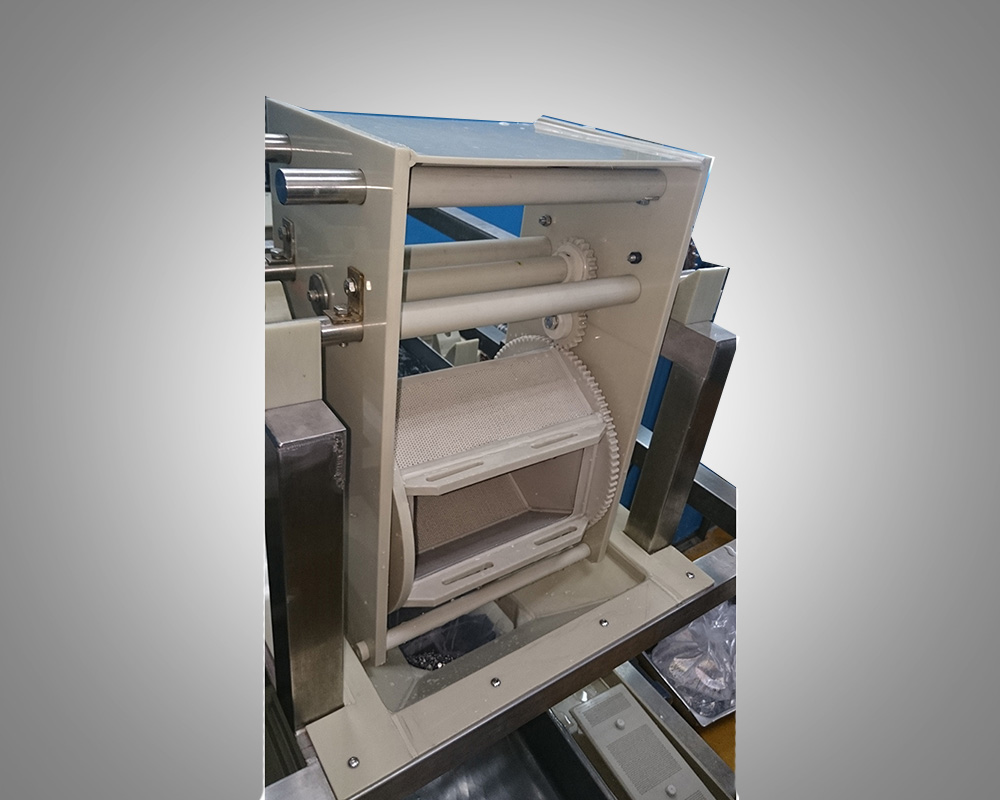

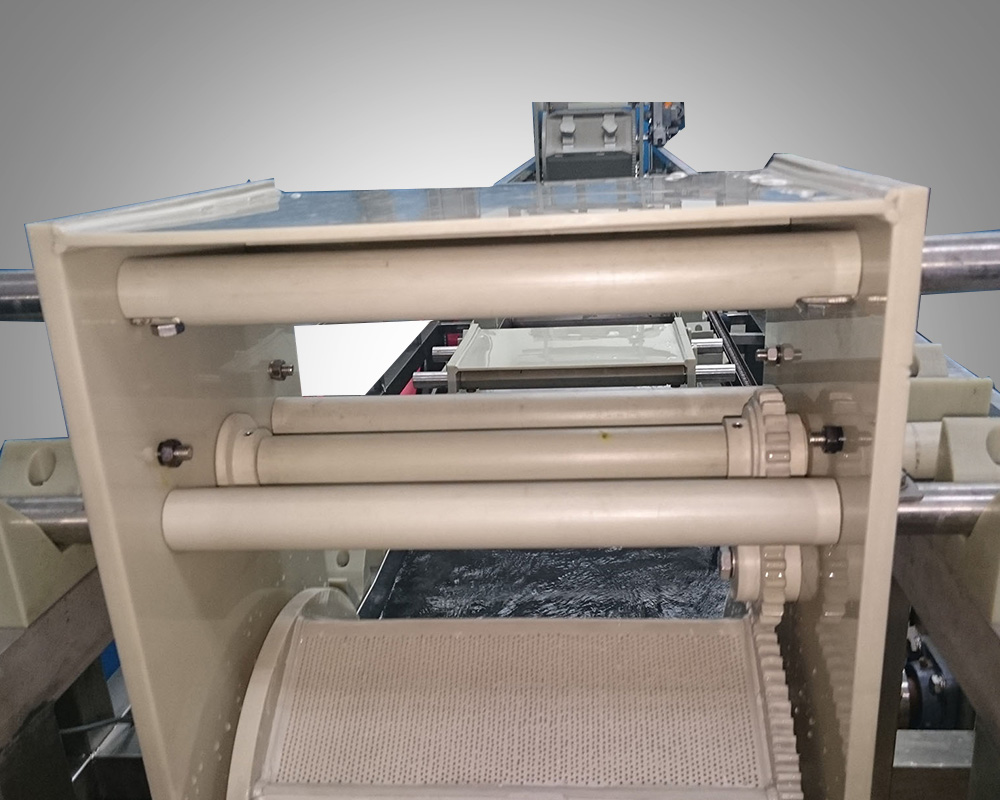

Customized System

We are specialized in system design, fabrication, wiring and system automation to customer requirement. The above system was designed to one of our customer production line to recycle the excess nylon powder, screened and segregate bigger powder and only the suitable powder to be reused in the system. The system has been successfully commissioned and handed over for commercial production in year 2019.

Drop us a message if there is special system requirement.

Mirae Ultrasonic Equipment

Ultrasonic Cleaning is powerful enough to remove tough contaminants, yet gentle with no damaging the substrate. It provides excellent penetration and cleaning in the smallest crevices and between tightly spaced parts in a cleaning tank.

In a process termed cavitation, micron-sized bubbles form and grow due to alternating positive and negative pressure waves in a solution . The bubbles subjected to these alternating pressure waves continue to grow until the reach resonant size. Just prior to the bubble implosion, there is a tremendous amount of energy stored inside the bubble itself.

Kyzen Chemicals

Distributor of Kyzen, USA cleaning chemical Southern Peninsular Malaysia

In 1990, two smart entrepreneurs became friends and then business partners and the world of environmentally responsible cleaning technologies hasn’t been the same since. Dr. Mike Bixenman and Kyle Doyel were both involved in solvent-based solutions, but for very different and distinct industrial manufacturing applications.

Now, KYZEN is celebrating three decades and a global success story as leader in creating environmentally responsible cleaning solutions and innovations for electronics assembly, metal finishing and advanced packaging.

This growth is the direct result of its unique culture and approach to the convergence of science and care. KYZEN uniquely understands the risks, takes on the big commitments and delivers with high-energy people, scientific excellence and the resources needed, all while MAKING A DIFFERENCE in the lives of people.